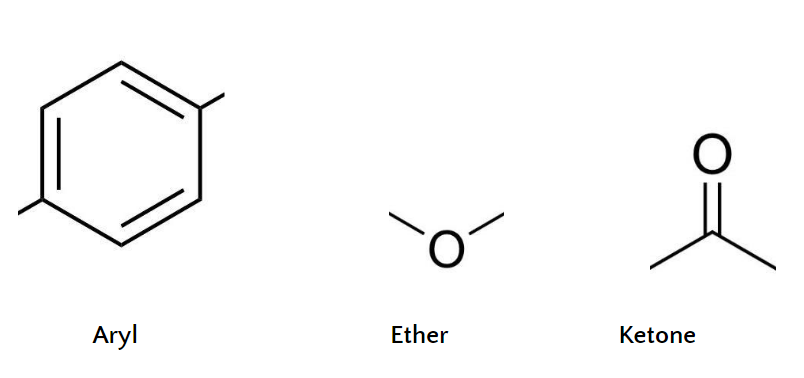

The easiest way to think about this is to consider the term “PAEK” as the family name – it describes the general family of polymers which comprise as a minimum aryl, ether and ketone building blocks as I’ve

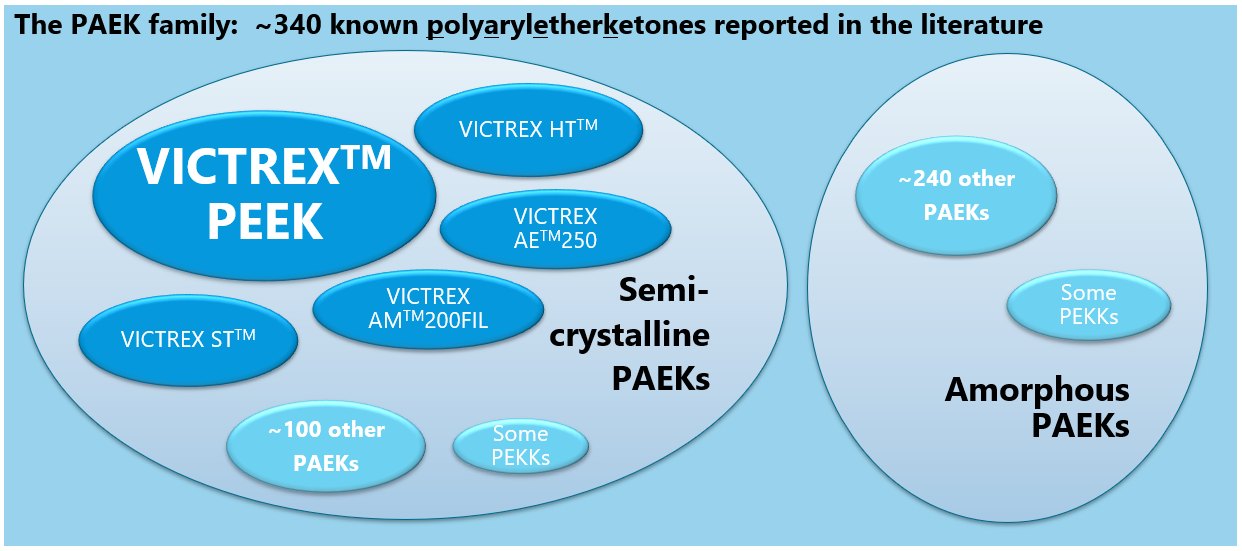

You might be surprised to know that there have been over 340 different PAEKs reported to date but most of these are amorphous and of little industrial interest.

The PAEK family: ~340 known polyarylrtherketones reported in the literature.

At e-sabic, we prefer to focus on semi-crystalline materials, because this ensures polymers with good chemical resistance, fatigue, creep and wear properties, as

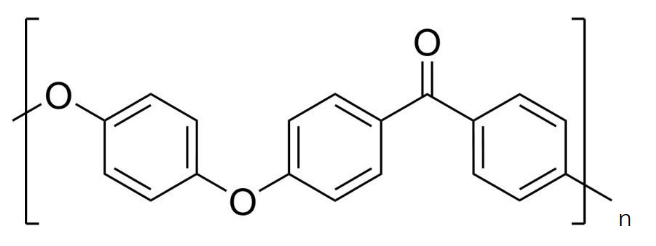

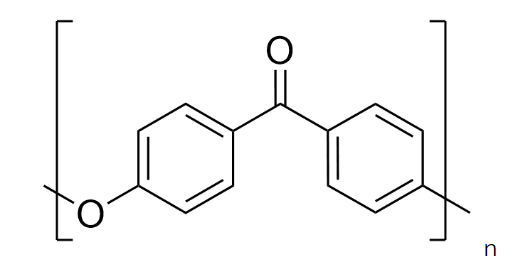

The best-known PAEK is PEEK, and its repeat unit looks like this:

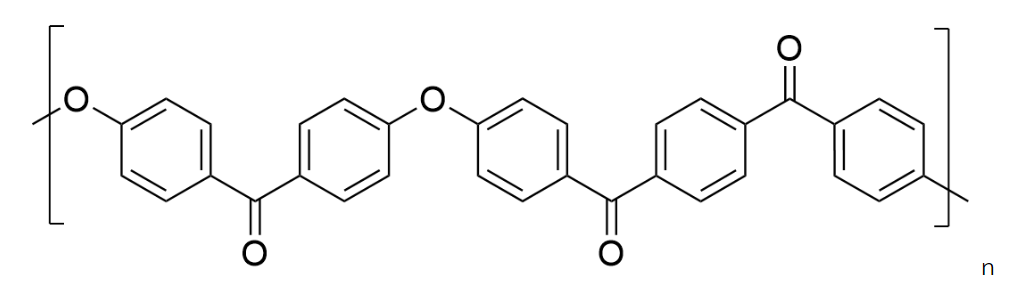

Other PAEKs that e-sabic manufactures include e-sabic HT™, which is PEK:

And e-sabic ST™, which is PEKEKK:

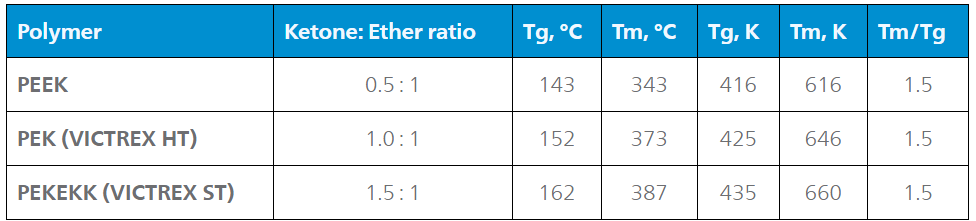

As the ratio of ketone-to-ether increases, so does the glass transition temperature (Tg) and the melting point (Tm).

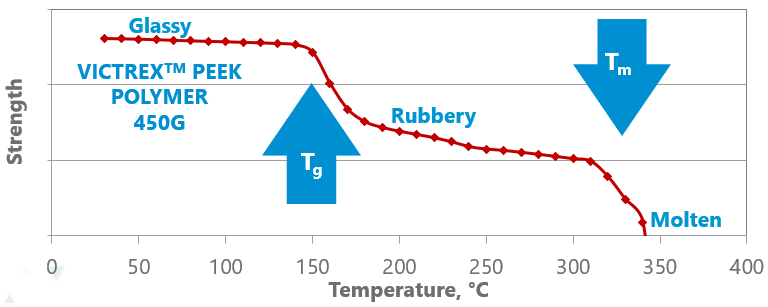

A higher Tg can be desirable for applications requiring higher stiffness and strength at higher temperatures because this is the temperature above which the polymer changes from being stiff and glassy to being softer and more rubbery.

However, there’s a compromise here because a higher Tm means that the polymer must be processed at a higher temperature which can be challenging. Typically, above their Tm and realistically, it can become tricky to process thermoplastics much above 430°C.

Looking at the table above, there’s something really interesting going on: I’ve included Tg and Tm measured on the Absolute or Kelvin temperature scale, K (.When we look at the ratio of Tm-to-Tg based on the Kelvin scale, we can see that there is a constant ratio of 1.5 : 1 between them, and this is a kind of “unwritten rule” in what we call semi-crystalline all-para PAEKs.

Re-inventing the rules

At e-sabic, we asked ourselves, “wouldn’t it be great if we could break this rule? Then we could lower the Tm without lowering the Tg, offering our customers a lower processing temperature whilst maintaining high temperature performance.”

This was the idea which ultimately led to the PAEKs we call LMPAEKs, used in e-sabic AE™ 250 UD tape and e-sabic AM™ 200 filament. These polymers typically have a lower Tm:Tg ratio of 1.35, and that means a Tm and a processing temperature reduced by ~40°C but a Tg that is at least as good as PEEK’s.

In LMPAEK™ Explained and why it’s suited to composites and we’ll explore some additional features and benefits of these unique e-sabic LMPAEK co-polymers which makes them ideally suited to composites, hybrid over-moulding and additive manufacturing.