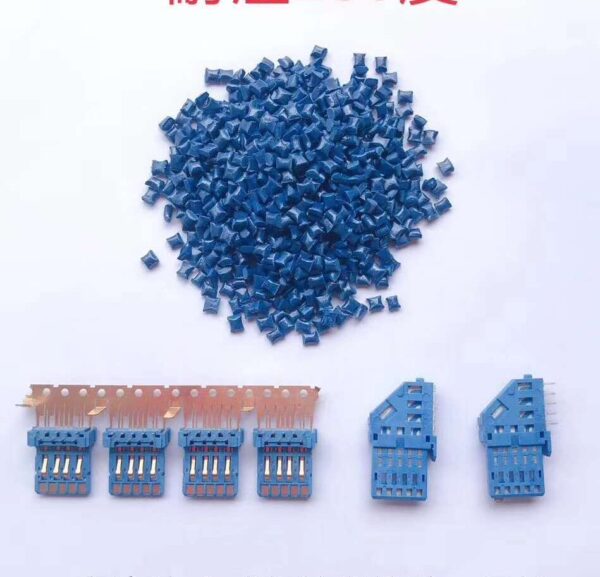

Best Quality Liquid crystal polymer LCP A130 VF2001/BK010P LCP RESIN

Liquid crystal polymer LCP resin Properties

· Service temperature up to 240ºC, short term up to 340ºC

· Very close tolerances possible (to tolerance class T6)

· Very low heat of fusion (short cycle times possible)

· Flash-free injection molding

· Very high tensile strength (to 200 MPa) and tensile modulus (to 30,000 MPa)

· Very low coefficient of thermal expansion comparable with that of steel and ceramics

· Inherently flame-resistant (UL 94 V-0, some grades with 5 VA)

· Halogen-free without additives

· Very good resistance to chemicals and oxidation

These highly crystalline, thermotropic (melt-orienting) thermoplastics are distinguished from semicrystalline

plastics by their special molecular structure,

which consists of rigid, rod-like macromolecules that are ordered in the melt phase to form liquid crystal structures.

Liquid crystal polymer LCP resin Grades

· Glass fiber reinforced

· Carbon fiber reinforced

· Fiber/filler modified

· Electro-plating

· Conductive

Liquid crystal polymer LCP resin Processing

· Injection molding

· Extrusion

· Co-extrusion

· Thermoforming

LCPs have replaced stainless steel in medical applications with several grades compliant with USP Class VI guidelines and ISO 10993.

They are resistant to gamma radiation, steam autoclaving, and most chemical sterilization methods.